AEROBAL presents the winners of the World Aluminium Aerosol Can Award 2025:

Excellent designs, innovative technologies and sustainable packaging concepts

The International Organisation of Aluminium Aerosol Container Manufacturers (AEROBAL) announced the winners of the World Aluminium Aerosol Can Award 2025 at its General Assembly in Paris at the beginning of February. For the first time, all member companies represented at the meeting voted directly for the best cans of the year. In previous years, the winners had been selected by a jury of specialist journalists from leading and renowned packaging magazines and media outlets. According to AEROBAL Secretary General Seifeldin Raslan Mohamed, the new voting procedure was introduced to ensure even stronger and more direct involvement of the members, as well as greater transparency and acceptance. Considering the high number of participants and the outstanding quality of the entries, this new concept has clearly proven successful. The prestigious AEROBAL Award has thus further strengthened its reputation as a globally recognised indicator of excellence and high-quality standards for aluminium aerosol cans in the international packaging market.

As in previous years, winners were selected in the categories “Already on the Market”, “Prototype” and “Sustainability”. The following products received top honours in this year’s competition: In the “Already on the Market” category, two products shared first place with an equal number of votes: the Hot Black Collection by the Turkish manufacturer Aryum and the PURE Range produced by Gulf Cans from the United Arab Emirates.

Aluminium Aerosol Cans already on the Market

The Turkish manufacturer Aryum won with its cans for the Hot Black Collection of the brand Bernard Dimitri from the Shaikh Mohd Saeed Group. The Shaikh Mohd Saeed Group is a legendary perfume company that has been creating extraordinary fragrances since 1954 and pioneered perfume manufacturing in the UAE. Today, the company manufactures, exports, distributes and retails well-known brands, including Bernard Dimitri. For the Hot Black Collection, Aryum produced the award-winning aluminium cans. The range includes four distinctive designs, each reflecting the character of its fragrance. Originally sold in standard cans, the line was upgraded to 360° embossed cans to protect the brand and enhance its visual value. This gives the 200 ml perfumed body spray cans their unique appearance. The characteristic embossing acts as a unifying design element, allowing the individual colour concepts of the range to unfold while maintaining a strong and coherent brand identity. The embossed “HOT” on the base of the can is a particularly original idea and a striking unique feature. This convincing new packaging concept helps set the Hot Black Collection apart from imitations and creates strong shelf appeal.

Aluminium Aerosol Cans already on the Market

The second winner in the “Already on the Market” category is Gulf Cans with its cans for the EGOX anti-perspirant deodorant. When the market-leading cosmetics company in Algeria set out to become the leader in the deodorant segment, it challenged its suppliers to create a bespoke packaging solution capable of shaping a strong and distinctive identity. The objective was clear: a can that is understated yet refined, simple yet unmistakable. The manufacturer responded with a design for the women’s deodorant spray that evokes femininity through a slender, elongated silhouette—elegant without excessive shaping, deliberately avoiding exaggeration in line with the purity suggested by the series name “PURE”. The design is defined by sharp, clean lines rather than rounded contours, ensuring a modern and distinctive look while avoiding anything commonplace. The blue of the spray cap is echoed in the EGOX logotype, whose colour variations correspond to the visual motifs of the individual fragrance notes and a subtle “NEW” print. The successful graphic design and outstanding printing quality create a harmonious premium appeal on the elegant white surface.

Winner Prototype Category

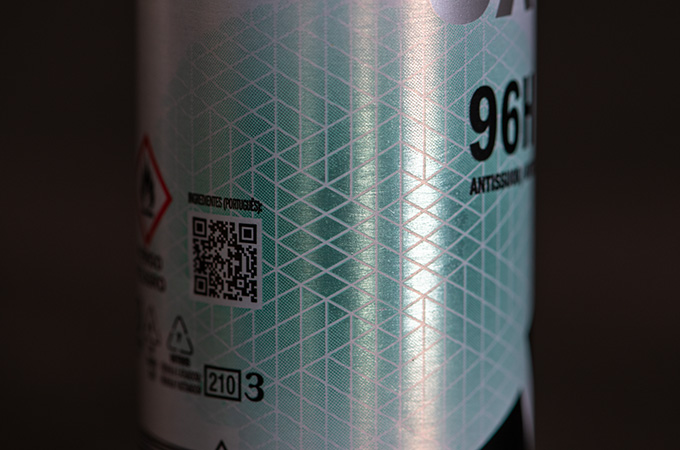

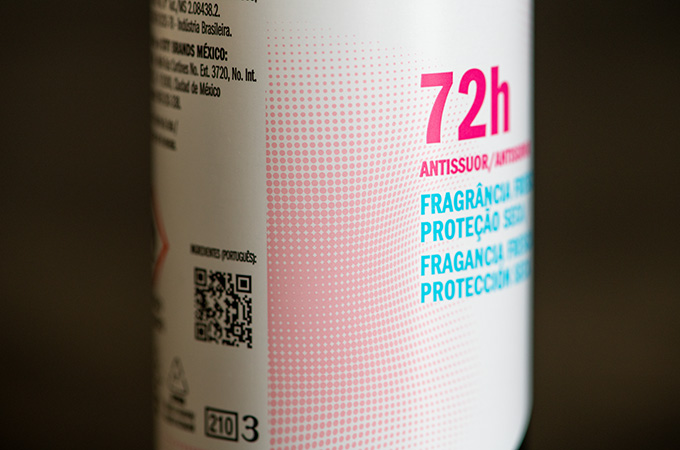

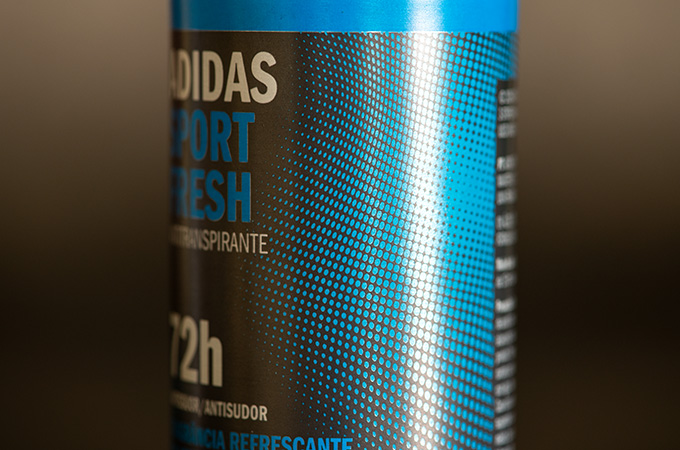

The winner in the “Prototype” category is an aluminium can for adidas produced by Trivium Packaging Brasil. The new adidas design project was born with a clear objective: to make the product stand out at the point of sale with a strong, modern visual identity aligned with the brand’s style. The challenge was to combine a retro touch with a sophisticated finish while maintaining clarity of essential information. Trivium met this demanding brief with an aluminium can that merges retro art and modernity to create a unique visual experience. The design features a pattern of small dots that softens the background and adds depth, while a special ink ensures the perfect fusion of metallic colours without visual imperfections. Each version of the packaging reflects the brand’s vibrant spirit and stands out clearly on the shelf. Beyond aesthetics, the project also delivers significant sustainability improvements. Trivium revitalised and unified the can model used, reducing its weight by 25%. By applying an advanced aluminium alloy and a revolutionary process that eliminates traditional ingot fusion, the company reduced carbon emissions by more than 50%, while maintaining strength and quality standards. In addition, the internal coating was reduced by 50%, significantly lowering VOC and CO₂ emissions. The result is a lightweight, functional and visually impactful package with a smaller environmental footprint—precisely what consumers expect from a global brand such as adidas.

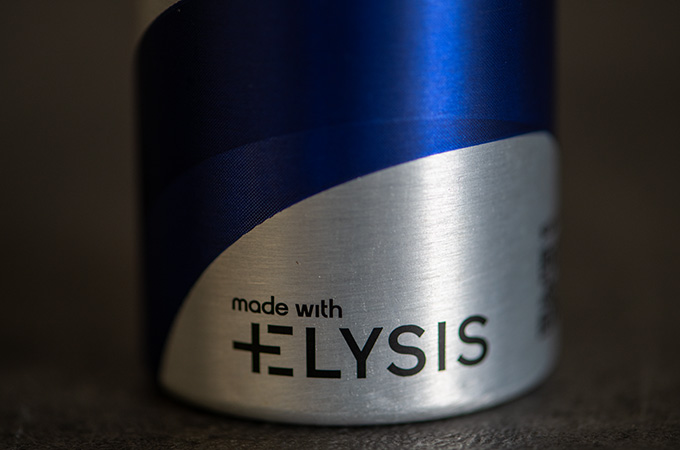

Winner Sustainability Category

In the “Sustainability” category, an aluminium aerosol can from the US-based manufacturer Ball Corporation received the highest number of votes. The winning product is the impressive result of a successful partnership between Ball, Alcoa and Unilever: the first ultra-low carbon aerosol can made with ELYSIS® aluminium. This project introduces the first aerosol can for personal and home care packaging made with aluminium produced using ELYSIS® carbon-free smelting technology, combined with 50% post-consumer recycled (PCR) content. The ELYSIS process eliminates all direct greenhouse gas emissions from aluminium smelting, generating oxygen instead of CO₂, and achieves an approximately 40–42% lower carbon footprint compared to conventional low-carbon aluminium. Through close collaboration along the value chain, Ball, Alcoa and Unilever have set a new benchmark for sustainable metal packaging while maintaining full performance and compliance. The project demonstrates how cross-industry partnerships can accelerate decarbonisation and create scalable models for climate progress across the sector. As the first consumer-ready aerosol can using carbon-free smelting technology combined with recycled content, it offers one of the lowest-carbon solutions in its category and paves the way for further sustainable packaging innovations.